How it Works

Exploring the

Bronze

PRocess

Bronze casting dates back to the ancient Chinese and the process has largely remained unchanged for thousands of years. The sculptures are cast using the traditional lost-wax method.

01

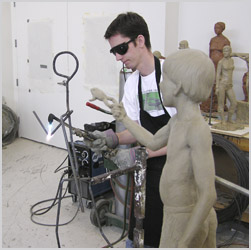

SKELETON

A steel armature is fabricated that will function as a ”skeleton” to hold the weight of the clay

02

Clay

The piece is sculpted using an oil based clay

03

Rework

The piece is worked and reworked until both the artist and client are pleased

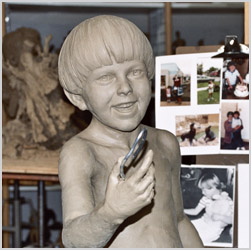

04

SCULPTURE

The finished life-size sculpture and small model

05

SECTIONS

Thin sheets of metal are used to divide the sculpture in to a predetermined number of sections

06

RUBBER

A latex rubber is applied to the clay sculpture. 5-6 coats are used to build up a sufficient thickness

07

Plaster

The molds are backed with plaster, which will give rigidity and support to the rubber

08

section mold

The plaster pieces are removed and the latex is cut down the center to create a two section mold

09

finished molds

The finished set of molds are collected

10

wax coating

The molds are coated with wax to create a copy of the clay original

11

replica

Wax is poured in, the mold is rotated to evenly coat, and the excess wax is poured out. This will create a hollow replica

12

remove wax

A finished wax being removed from the mold

13

Finished wax

One wax piece is finished

14

Runners & Cup

The pieces are touched up. Wax runners and cups are attached, which will later act as funneling system to for the bronze

15

Ceramic Coating

Pieces are coated in a liquid ceramic and dried. This will be repeated 7-8 times to build a thick ceramic shell. The shell becomes another mold

16

First coat

Finishing the first coat of liquid ceramic

17

sand coat

Next the piece is coated in sand. This will help dry it quicker and add mass to the ceramic

18

hollow shell

The ceramic is chipped away from the bottom of the cup. The piece is heated and the wax melts, leaving a hollow ceramic shell.

19

Finished wax

One wax piece is finished

20

Runners & Cup

The pieces are touched up. Wax runners and cups are attached, which will later act as funneling system to for the bronze

21

Ceramic Coating

Pieces are coated in a liquid ceramic and dried. This will be repeated 7-8 times to build a thick ceramic shell. The shell becomes another mold

22

OVEN

The ceramic shell are also heated, to prevent them from shattering from the shock of the molten bronze

23

COOLING

The shells are removed from the oven and placed in a sand filled box with the cup facing up

24

BRONZE POUR

The cup acts as a funnel and the runners carry the bronze to the piece

25

shell cleaned

Once cooled, the ceramic shell is chipped away. Then the cup and runners will be cut off.

26

finished pieces

A finished set of bronze pieces ready to be reassembled.

27

welding

Using heli-arch welders the bronze pieces are welded back together. The sculpture is ground and polished to create a seamless finish.

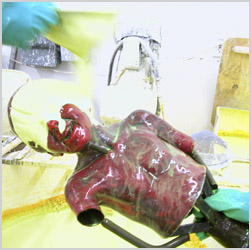

28

chemicals

The sculpture is heated and treated with chemicals that oxidize the bronze changing its color to the desired effect

29

final piece

The finished piece is not only beautiful but strong and durable able to last generations!

FIN

purchase

Please click the button below to learn more about how to commission a unique piece!